The equipment is composed of fabric cord automatic fixed-length servicer, rubber sheet automatic fixed-length servicer and cutting device, and sleeve building head&platform.

Fabric cord automatic fixed-length servicer inlcuding: frame, fabric cord winding up device, brake(for adjusting the fabric cord tension), peeling off device(for seperating the fabric cord and rubber sheet), and setting length fabric cord conveying device.

Rubber sheet automatic fixed-length servicer and cutting device including: frame, rubber sheet winding up device, brake, peeling off device, setting length rubber sheet conveying device, and cutting device.

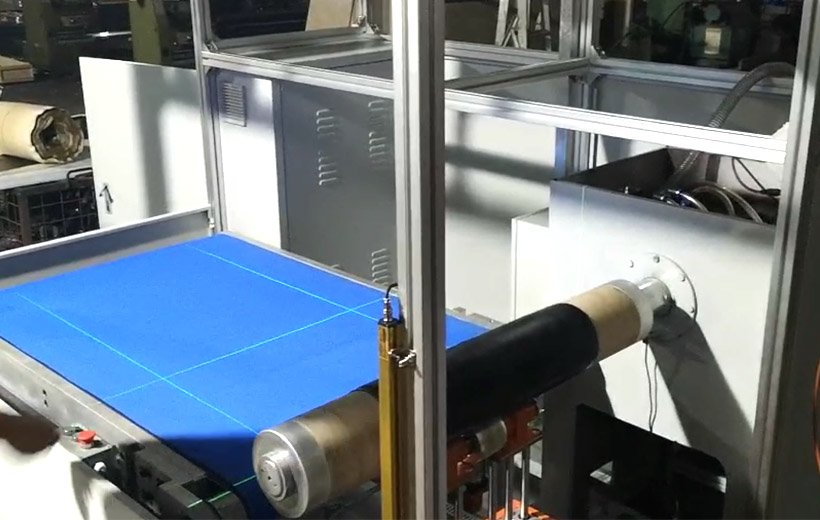

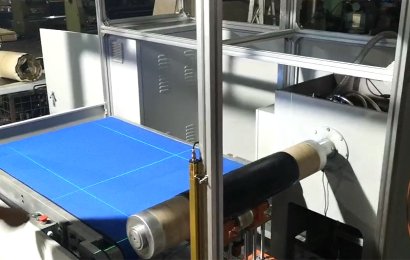

Building head & platform machine including: frame, building platform, laser positioning lights(the angle and laser width can be set), building head, and pressing roller device(according to the products, you can select whether need to press or no).

Electronic control: The main control adopts PLC (Mitsubishi) programming, and HMI adopts dual touch screens (Mitsubishi), and the building, rubber sheet and fabric cord conveying are controlled separately. There is a storage function to save the specification parameters. Buttons are installed at the corresponding positions of the building machine for easy operation.